Automated Photomanipulation

A laser module for automated photomanipulation on the ACQUIFER Imaging Machine

Easily parallelize complex photomanipulation experiments, such as photo-damage, photo-conversion, optogenetic or compound uncaging with the photomanipulation module for the ACQUIFER Imaging Machine.

The module is an optional hardware upgrade relying on the moving optics of the Imaging Machine. The laser is automatically positioned under specimen mounted in microtiter plates (or other sample holders), before precise photomanipulation by scanning optics.

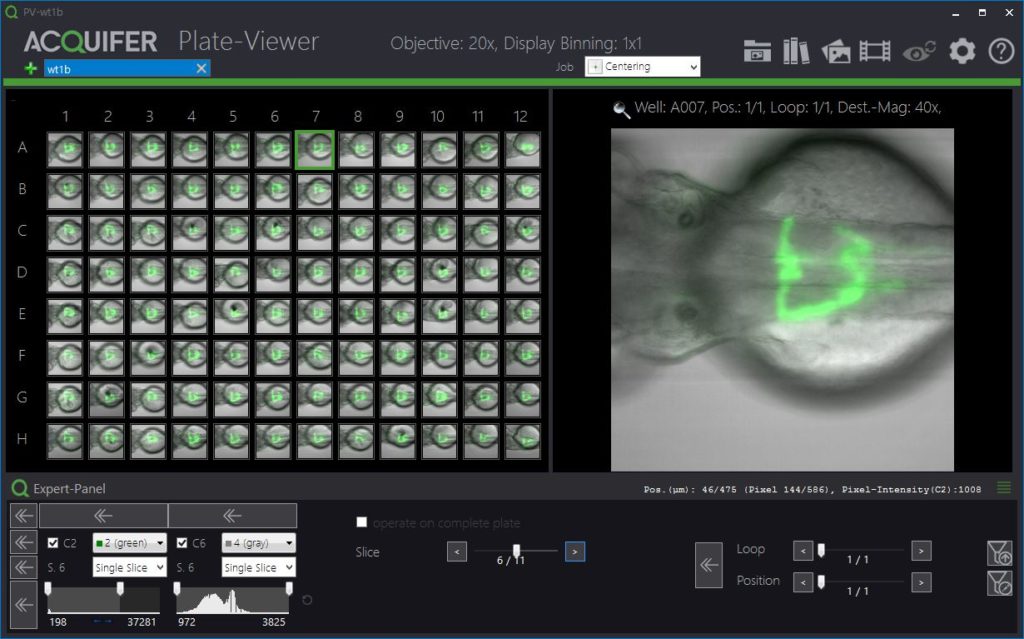

The entire photomanipulation workflow is integrated in the ACQUIFER Plate-Viewer software, a tool for smart imaging and supervised feedback microscopy.

The module was developed in collaboration with Rapp Optoelectronic, Wedel, Germany who has over 20 years of experience in high-performance photomanipulation and advanced light microscopy techniques.

Potential applications of automated photomanipulation

- Photodamage

- Photoconversion

- Uncaging

- Optogenetics

Data by Dr Jana Heigwer (Westhoff lab, University Children’s Hospital, Heidelberg)

Photomanipulation Workflow

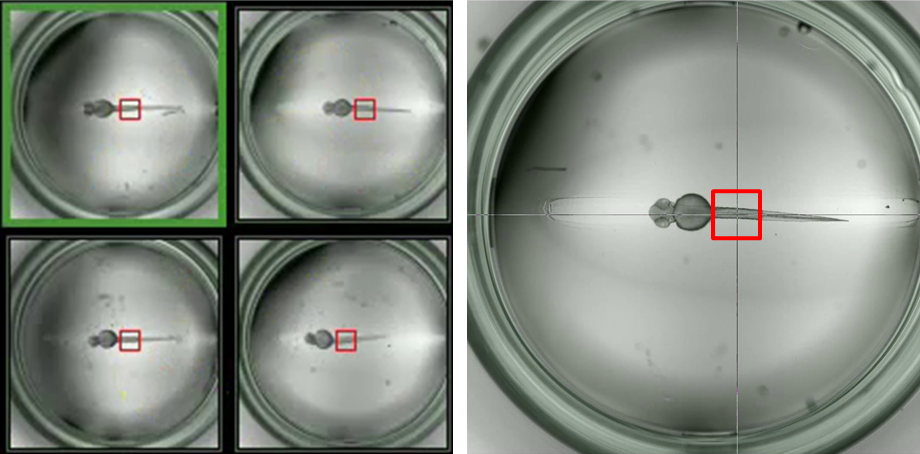

1) Pre-screen and identification of ROIs

- Generation of pre-screen data (e.g. using 2x objective) at low resolution

- Selection of areas of interest for higher-magnification imaging via the Plate-Viewer

2) Higher resolution imaging

- Imaging of selected areas at higher magnification (e.g. 20x objective) using smart imaging

- Acquisition of pre-photomanipulation reference dataset

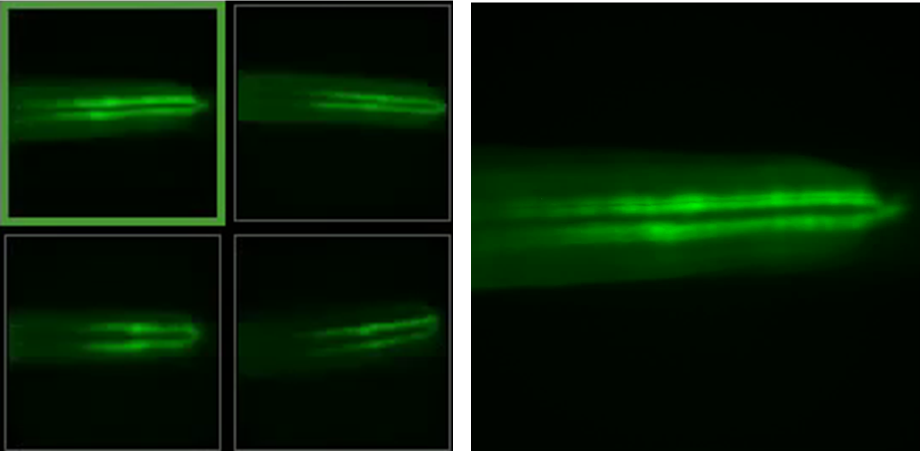

3) Annotation of regions for lasering

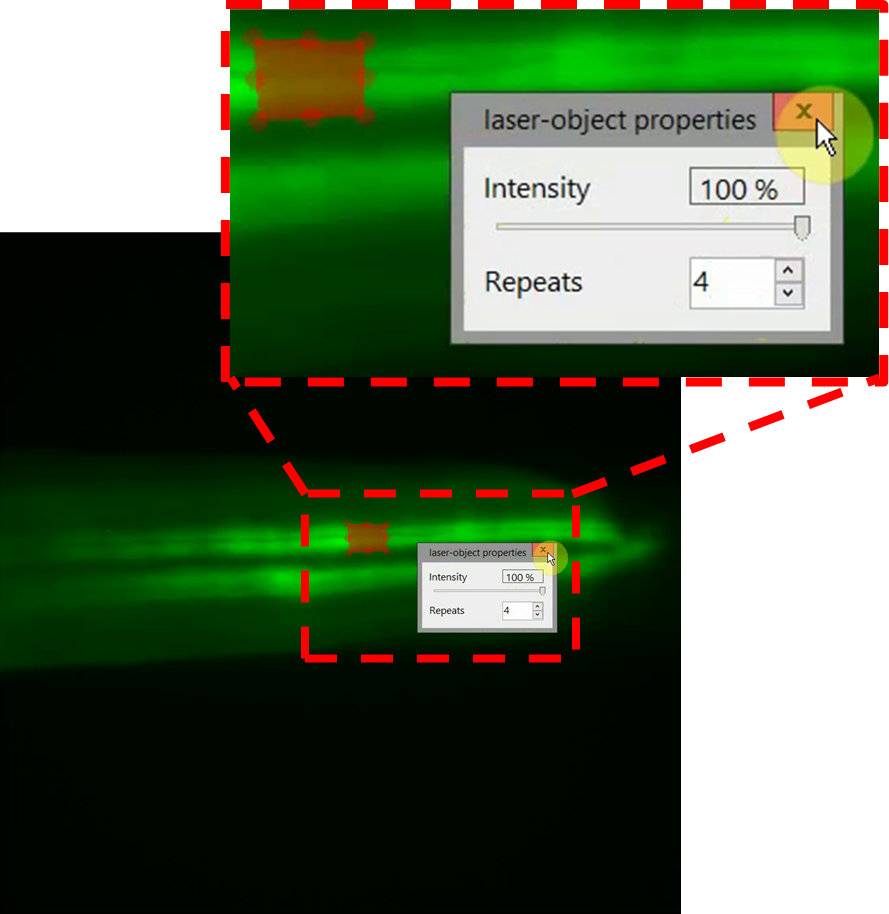

- Definition of regions of interest (ROI) for targeted laser illumination using the Plate-Viewer

- Flexible shapes: lines, polygons, filled and unfilled areas

- Possibility to define multiple ROIs per field of view

- Custom laser settings (intensity, iterations) for every ROI

4) Lasering and post-acquisition

- Automatic photomanipulation (e.g. tissue damage) of entire microtiter plates

- Acquisition of post-photomanipulation dataset